Pulp Molded Tableware Production Line

Pulp Molded Tableware Production Line

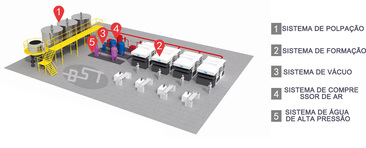

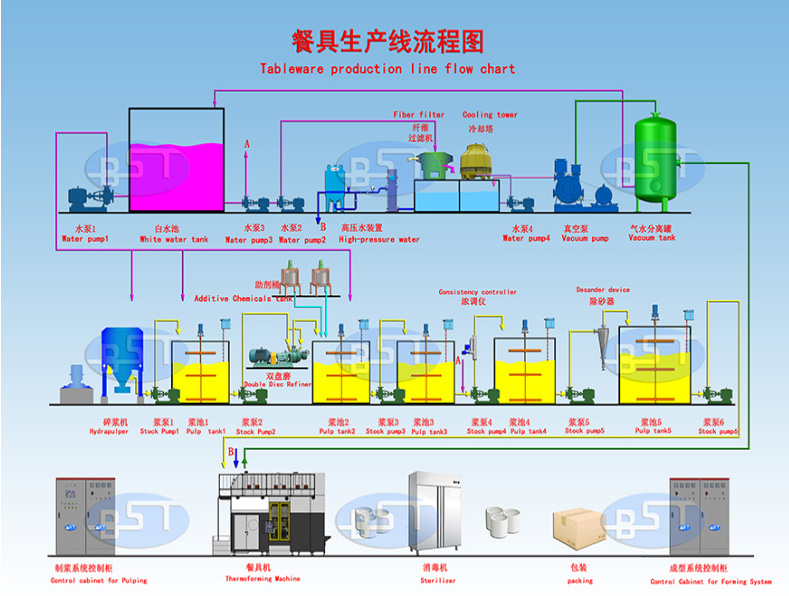

The biggest feature of the host system is the integration with forming, hot pressing, trimming and stacking. It is automatically and continuously completed without manual transfer, and can be achieved through the line without removing the mold and changing the mesh(completed in 5 minutes). This greatly saves the site, labor and power consumption, and improves the start-up rate, product qualification rate and product quality and provides easy maintenance.

The specific parameters are as follows:

| Models | TSA3-11580 |

| Equipment Composition | Forming,3 Phase Hot Pressing, Trimming, Stacking |

| Platen Size | 1150mm*800mm |

| Capacity Each Machine | 1Ton/day(basing on 9 inch round dish, 17g) |

| Outline Dimension(mm) | L 13000 * W 3230 * H 3850mm |

| Forming Type | Reciprocating pulp suction and forming |

| The forming minimum shut height is 130mm. (mm) | 120 |

| Hot-press standard mold closing height(mm) | 140 |

| Forming Pressure | 5T |

| Hot Pressing pressure | 40T |

| Trimming Pressure | 60T |

| Product Height(mm) | ≤65 |

| Production Agle(度) | ≥10 |

|

Product transfer method |

Servo drive chain drives mesh frame transfer products |

|

Heating Method Electricity |

Electricity or Thermal Oil + Electricity |

| Control method | PLC + touch screen |

| Remarks | The above parameters are for reference. Due to the continuous development of technology, relevant data will be continuously updated |

The following data is the reference configuration of the production line, and can be customized according to the specific needs of customers.

| Models | Output Capacity | Floor | Staff | Electricity | Water |

| TWB4000 | 4Tons/day | 24 * 88Meters, height ≥5M | 5Persons/shift | 1000-1050KW/hour | 0.4-0.6Tons/hour |

| TWB8000 | 8Tons/day | 24 * 120Meters, height ≥5M | 9Persons/shift | 1900-1950KW/hour | 0.9-1.1Tons/hour |

| TWB10000 | 10Tons/day | 24 * 144Meters, height ≥5M | 11Persons/shift | 2300- -2400KW/hour | 1-1.3Tons/hour |

| TWB20000 | 20Tons/day | 36 * 184Meters, height ≥5M | 22Persons/shift | 4500-4600KW/hour | 2.4-2.6 Tons/hour |

| TWB30000 | 30Tons/day | 40 * 224Meters, height ≥5M | 33Persons/shift | 7000-7100KW/hour | 7-3.9Tons/hour |

| TWB40000 | 40Tons/day | 40 * 264Meters, height ≥5M | 44Persons/shift | 9035-9450KW/hour | 4.9-5.1Tons/hour |

| TWB50000 | 50Tons/day | 264 * 52Meters, height ≥5M | 54Persons/shift | 11400-11500KW/hour | 6.2-6.4Tons/hour |

Online Message

Paper Mold Equipment Solution

Copyright © 2020 Foshan BeSure Technology Co., Ltd. All rights reserved 粤ICP备19145832号