Automatic Industrial Packaging Pulp Molding Production Line

Number of views:

1055

Automatic Industrial Packaging Pulp Molding Production Line

Retail price

100000.0

$

Market price

0.0

元

Number of views:

1055

Product serial number

Number of units traded within one year:

0

set

Quantity

-

+

Stock:

997

1

Details

Parameters

The host system consists of a forming machine and a single-layer high-efficiency drying line. Flexible production; can produce a variety of products; high efficiency and energy saving.

Specification as below

| Model |

IP3000 IP8000 |

| Production line composition | Forming System:Forming System: reciprocating forming (with the function of washing mold / product burrs, equipped with preheating system) Drying System:single layer high efficient drying line Hot press system: Manual hot press |

| Forming platen size | 1200x800 1600x800 |

| Design capacity of production line(based on 30cell egg tray) | It is determined by the product produced (involving product layout / product weight) |

| Forming type | aspiration et formation de la pâte alternative |

| Product height | ≤200mm |

| Heating fuels | Gas, Thermal oil, LPG, LNP or steam(if with steam, the drying system is to be lengthened basing on the specific output capacity) |

| Control method | Méthode de contrôle PLC + écran tactile |

| Remarks | Les paramètres ci-dessus sont fournis à titre de référence. En raison du développement continu de la technologie, les données pertinentes seront continuellement mises à jour. |

1.High efficient and energy saving

6 layer high-efficiency drying line, saving natural gas.

2.high degree of automation

4-5 operators are needed only.

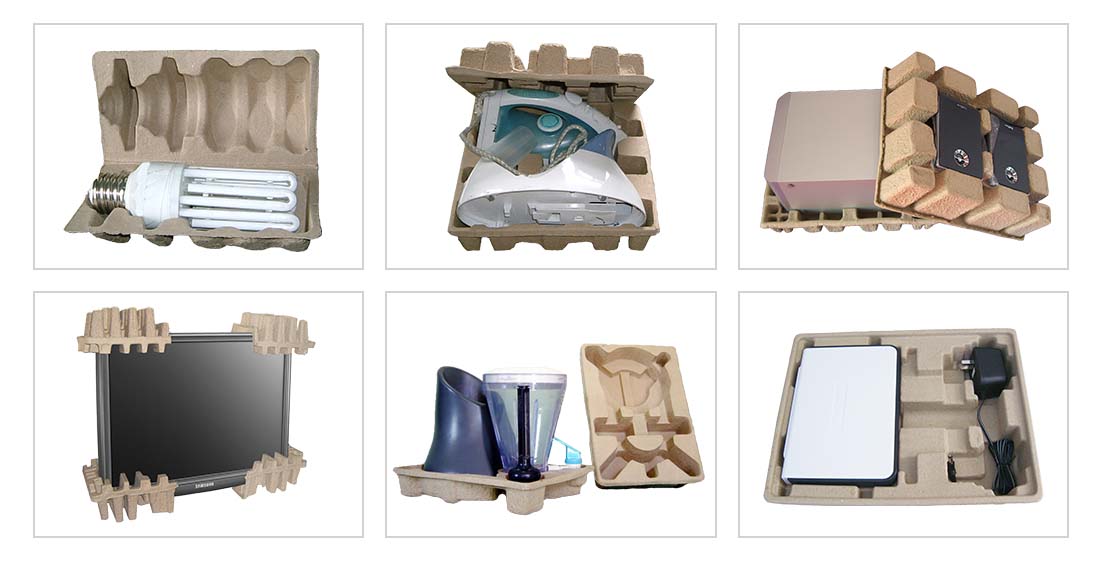

3. Production flexible

Can flexibly produce electronic product packaging, small home appliance packaging, industrial parts shockproof inner packaging, paper Care, paper lining,etc.

4.Easy Operation and Maintenance

The operation is simple, and ordinary operators can perform maintenance.

The following data is for reference only, and can be customized according to the specific needs of guests.

| Models | Output Capacity | Floor | Staff | Electricity | Water |

| IP4000 |

4Tons/day |

48*24 Height≥5M | 3 persons/shift | 150-160KW/Heure | 0.4-0.5t/H |

| IP6000 | 6Tons/day | 66*24 Height≥5M | 5 persons/shift | 220-230 KW/Hour | 0.5-0.6t/H |

| IP8000 | 8Tons/day | 66*24 Height≥5M | 5 persons/shift | 320-330KW/Hour | 1.0-1.1t/H |

Keyword:

Industrial Packaging

pulp molding

production line

forming system

Environmentally friendly products

Energy saving

Scan the QR code to read on your phone

Previous

None

Next

None

There are no products in your shopping cart, go and choose a product!

Online Message

客户留言

Description

Paper Mold Equipment Solution

Automatic pulp molded cup lid production line

Used to produce pulp molded coffee cup lids, beverage cup lids and other products.

Automatic pulp molded tableware production line

Used in the production of pulp molded tableware such as lunch boxes, soup bowls, and dishes.

Automatic pulp molding tray production line

Used to produce pulp tray tray products such as egg tray, fruit tray, beverage tray, coffee tray, medical tray, etc.

Automatic pulp moulded egg carton production line

Used to produce all kinds of pulp molded egg boxes.

Full-automatic pulp molding quality work bag production line

用于生产工艺品、手机、日用品、数码产品等纸浆模塑精致高档内衬或外包装。

Automatic pulp molded urinal production line

Used in the production of medical supplies such as pulp molded urinals.

Automatic pulp molding ordinary work bag production line

It is suitable for the production of pulp molded electronic product packaging, small home appliance packaging, industrial component shockproof inner packaging, paper trays and paper linings.

Pulp mould

Commonly used mold types include pulp molded tableware molds, pulp molded tray molds, pulp molded egg box molds, pulp molded tool bag molds, pulp molded urinal molds, etc.

Pulp tableware products

It can be customized, with a variety of styles and increasingly used. It will replace other non-degradable tableware products such as plastic and foam. Healthy, safe, pollution-free, degradable and environmentally friendly. Common types of pulp tableware: lunch boxes, soup bowls, dishes, cup lids, etc.

Copyright © 2020 Foshan BeSure Technology Co., Ltd. All rights reserved 粤ICP备19145832号