Full-automatic pulp molding quality work bag production line

Full-automatic pulp molding quality work bag production line

1. Overview of production line:

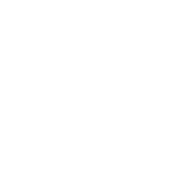

Product name: Fully automatic fine industrial packaging pulp molding production line

Applicable industries: fine electronic products industry, wearable smart device industry, electronic appliances industry, carton industry, printing industry, paper industry, wine industry, furniture industry, toy industry, cosmetics industry, jewelry industry

Uses: production of mobile phone packaging, wearable smart device packaging, camera packaging, gift packaging, jewelry packaging, cosmetic packaging, boutique electronic product packaging, etc.

Output: 2-10T/day (specific output depends on production line model)

Custom processing: Yes

Installation and commissioning: our company sent 2 engineers to the buyer for guidance, installation, commissioning and training

Warranty period: the whole machine is guaranteed for 1 year, and the machinery and main structural parts are guaranteed for 3 years

Production line configuration: This production line is standard configuration, and can also be customized according to the actual needs of guests.

Second, the product characteristics of the production line:

1. The raw material is mainly straw pulp board, environmental degradation

2. High degree of automation, exquisite product appearance, can be used for internal and external packaging

3. Pulp products can replace all kinds of plastic products.

Third, the production line capacity and configuration: The following data is the reference configuration of this production line, and can be customized according to the specific needs of customers.

| Model | Output Capacity |

Floor |

Staff |

Electricity |

Water |

| FP2000 | 2000kg/day | 24*18m,Height≥6m | 3persons/shift | 210-230kw/hr | 0.05-0.1t/hr |

| FP3000 | 3000kg/day | 24*18m,Height≥6m | 6persons/shift | 300-320kw/hr | 0.1-0.2t/hr |

| FP4000 | 4000kg/day | 24*36m,Height≥6m | 7persons/shift | 410-430kw/hr | 0.2-0.3t/hr |

| FP6000 | 6000kg/day | 24*48m,Height≥6m | 9persons/shift | 580-600kw/hr | 0.3-0.4t/hr |

| FP8000 | 8000kg/day | 24*72m,Height≥6m | 11persons/shift | 1070-1090kw/hr | 0.5-0.6t/hr |

| FP10000 | 10000kg/day | 24*72m,Height≥6m | 14persons/shift | 1280-1300kw/hr | 0.6-0.7t/hr |

4. Main structure of production line

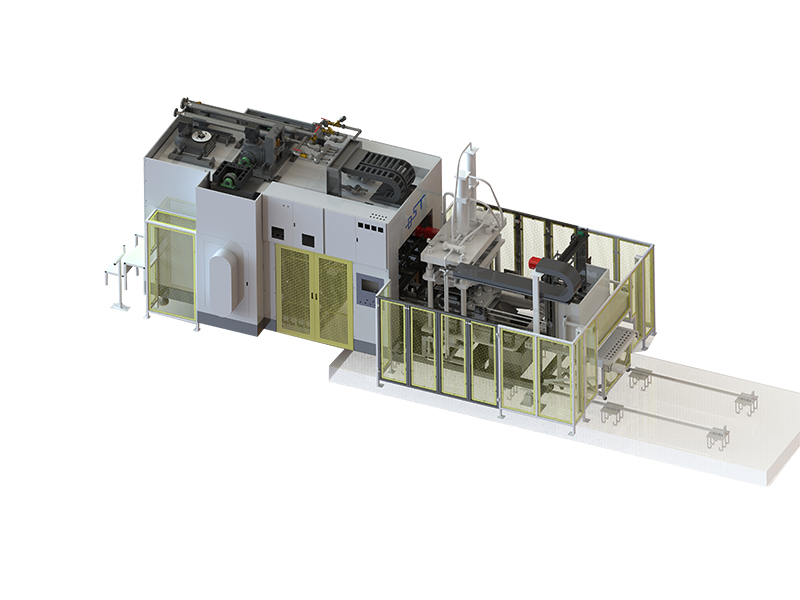

Pulp-making system: (The waste paper from old newspapers, magazines, cartons, etc., is crushed, sieved, and chemical additives are added into a slurry with a certain concentration for molding.)

Forming hot pressing system: (The slurry is uniformly attached to the special forming mold through vacuum action to form a wet blank product, and then transferred to the hot pressing film, the finished product is produced through the drying and hot pressing process, and then transferred out, Stacked together.)

Vacuum system: (Provide vacuum for the host molding products)

Air Compression System (Provide compressed air for the host to transfer products)

High water pressure system (provide high pressure water for the host to clean the mold)

Product post-processing (gluing machine, laminating machine)

5. Flow chart of production line:

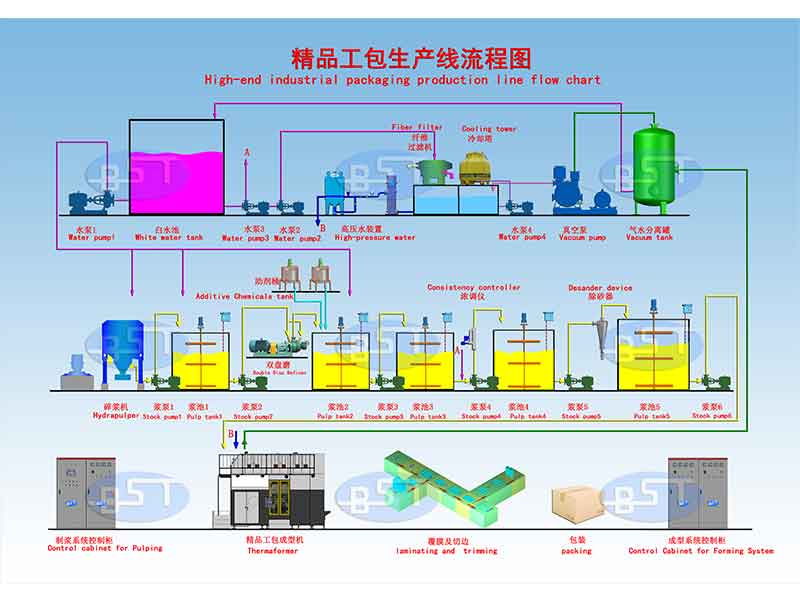

6、first-line accessories cooperation brand

七、设备可生产的制品

|

Fine work bag production line products |

Fine work bag production line products |

Fine work bag production line products |

|

Fine work bag production line products |

Fine work bag production line products |

Fine work bag production line products |

五、生产线流程图:

四、生产线主要结构

制浆系统:(将旧报纸、杂志。纸箱等废纸,经过碎解、筛选、添加化学助剂等工艺调配成一定浓度的浆料,供成型使用。)

Online Message

Paper Mold Equipment Solution

Copyright © 2020 Foshan BeSure Technology Co., Ltd. All rights reserved 粤ICP备19145832号